How to install Differential Pressure Switches for variable flow primary pumping system

(the copy rights belongs to ZHOU ENSI LTD, reproduce is not allowed)

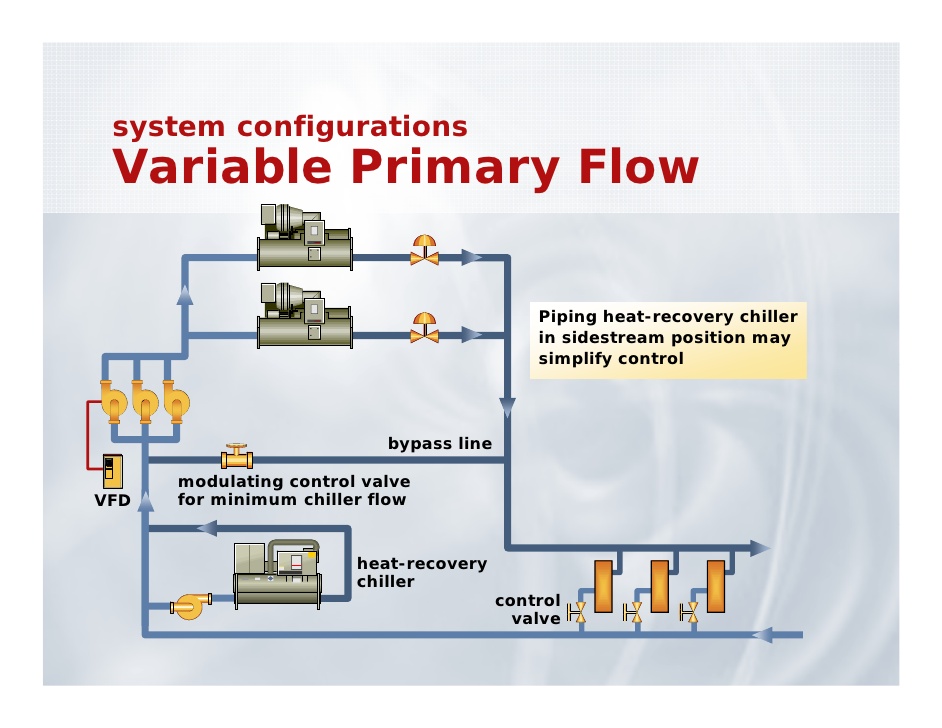

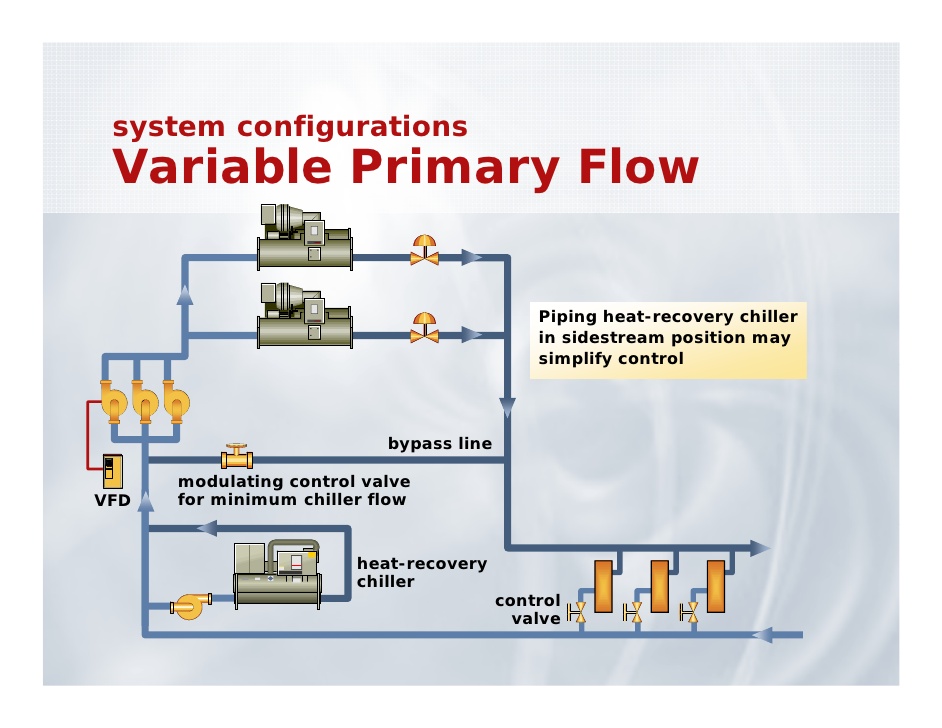

The variable flow primary pumping system is the most economical and energy efficient chilled water system available. Applications All applications which require chilled water can benefit from the performance optimization and operating cost savings of variable flow primary pumping. It utilize a variable capacity cooling system and a variable flow water pumping system to modulate cooling and water flow to meet chilled water needs wide range of sizes of variable capacity.

[variable flow primary pumping system]

It is very important to monitor the water flow of the VPF system, if no flow, the instrument must stop; if not, the machine will be destroyed. So many user of VPF install our Differential Pressure Type Flow Switch to detect the water flow, if no flow, our DPS will send alarm signal to turn off the machine automatically.

Then how to install the differential pressure type flow switches in the variable flow primary pumping system?

GE-511A Differential Pressure Switches with Brass Body to detect the water flow of pump

1. The differential pressure flow switch, which is installed in the heat exchanger system, shall be welded with pressure measuring interface at the inlet and outlet of the heat exchanger;

2. The water inlet pipe is connected with "+" end, and the water outlet pipe is connected with "-" end;

3. The pressure pipes and shells on both sides of the flow switch shall be insulated to proof frozen;

4. The product provides SPDT contacts, i.e. one normally open and one normally closed contact, can be selected for access to the controller, and the factory default leads out the normally open contact;

5. The differential pressure flow switch can be directly installed by the factory, and the wire can be directly connected to the controller of the water chiller, so as to reduce the possibility of the installation error of the field personnel, which will undoubtedly increase the cost of the manufacturer, but it can significantly reduce the technical consultation and maintenance costs caused by the flow switch;

6. At the same time, the differential pressure switch can also be provided to the field installation personnel as an accessory, and the installation can be carried out on site according to the situation. The user can weld a G1 / 2 "inner wire on the site water inlet and outlet pipe, install a small ball valve, and then install a G1 / 2" - 1 / 4 "SAE (7 / 16" - 20unf) joint, and pass the "1 / 2" - 1 / 4 "SAE (7 / 16" - 20unf) joint 6.35mm the bell mouth of the copper tube is connected with the flow switch, but the flow switch needs a fixed bracket;

GE-511C Differential Pressure switches with stainless steel body

GE-511C differential pressure type flow switches adopt stainless steel material,...

7. The advantages of site installation can be flexibly selected according to the site conditions.

In addition, the "+" end interface of the differential pressure switch can be G1 / 4 ", and the" - "end interface is 1 / 4" SAE (7 / 16 "- 20unf). The user can weld the G1 / 2" internal thread at the water inlet end, and then change it to G1 / 4 "external thread adapter after G1 / 2", and then connect the G1 / 4 "internal thread ball valve, and then screw the water flow switch directly on the valve. The other end is connected in the same way as the previous one. This connection method is the same as the previous one The method has the effect of anti stupidity, and the user can install the "+" and "-" terminals correctly on site;