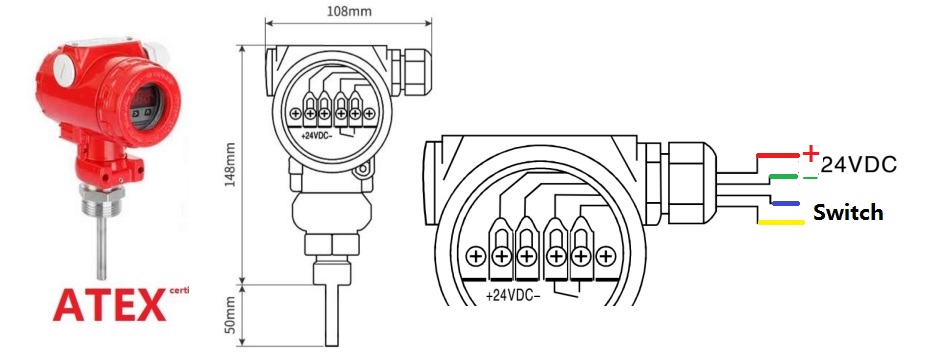

GE-325 Digital Flow Switches adopt the technology of thermal diffusion principle with ATEX explosion-proof shell, probe the built-in heating module and thermal module, the flow switch converts the temperature difference signal into the corresponding electrical signal, so as to display and control the flow of the medium. It adopt the cast aluminum explosion-proof shell, the explosion-proof level up to ExdIICT6.

ExdIICT6 ExdIIBT4

2. The Connection with Pipe

* Make sure the thread of the joint is suitable. Make sure the size of the joint before installation to avoid damage to the product.

* Pay attention to protect the wiring plug and bottom probe when installing, and completely avoid any strong collision and injury.

* After installation, make sure that the joints are free of leakage and other abnormal conditions.

* Use appropriate tools when tightening the flow switch to avoid damage and looseness of the product.

3. Wire Connection for the digital Explosion-proof flow switch

* Must cut off the power before open the shell

* Please use explosion-proof cable, or remove the waterproof gran connector to add the explosion-proof threading tube.

4. Adjust for the digital flow switch

4.1 functional Control Key

The description of the control keys from left to right are: set key, forward key and backward key. Their functions are as follows:

Set: the setting key is used for parameter selection, setting and entering the main menu from the working interface;

< : shift key, which is used for forward turning of parameters and forward cycling of data modification bits. When the pipeline water flow is in static state, when the display is zero below, long press this key to return to zero.

↑ Up key: used for parameter abandonment, back flip and data bit increment.

4.2 Parameter Function Description

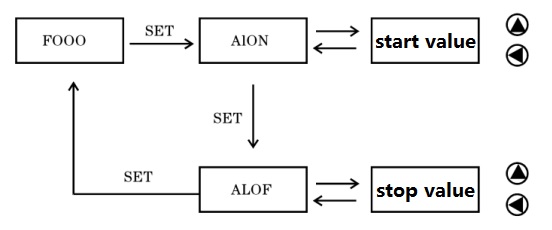

ALON: alarm start value, factory default 45% (when the flow value is greater than 45% of the maximum flow, the switch is on)

ALOF: alarm stop value, factory default 40% (when the flow value is less than 40% of the maximum flow, the switch is off)

4.3 setup procedure

4.4 debugging

C. After 1 minute, the flow switch will display the flow percentage normally, so that the following settings can be made:

1) If the water flow static state display is not zero, it can be reset to zero by long pressing the middle shift key (<) for three seconds.

2) If the water flow static state display value is more than 30%, long press the shift key (<) does not work, and at the same time press the set key + (<) key to display pass, Press the up key (↑) to display 000 and the shift key to input 110, press the set key until the words “AD" is displayed, then press the up key to display the zero value, press the shift key once to save the zero value, then open the valve, after the water flows at the highest speed, press the up key to save the full value, then press the set key to exit the setting and enter the detection state.

Related Products

EX Thermal Flow Switches with Digital Screen

GE-325 series Thermal Flow Sensor is designed as Explosion Proof type,...

Contact: Mr.Robert

Phone: 0086-13166369204

Tel: 400-852-8332

Email: hongkong@ayite.net

Add: Building 17 &22, No.2928, Chuan Zhou Highway, Shanghai, 201319, China